Construction

& Safety

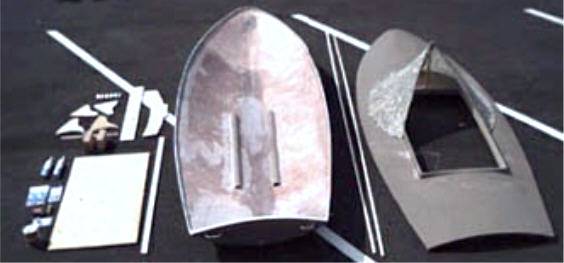

Construction

Duck

hunters by nature are hard on their equipment. We build our boats to

stand up to those demands. Our boats are constructed of all hand-laid fiberglass (no chop guns for us). We use 4 layers of

HAND-laid fiberglass, for a very heavy duty construction. Stand on the

deck, jump down from the dock. Donít worry about it. Our boats are

built to take it.

From the

30 years of boat building experience of previous owner Don Warren, to the high

performance fiberglass airplane construction experience of

Safety

Your

safety is our #1 concern.

It all

starts with our hull design. Over the past 150 years, there has been

little change in the hull shape of these duckboats

for one reason: It works! You wonít find a more stable sneak boat.

The round displacement hull gives great stability in the roughest water.

During testing of these boats, we literally stood on the side of the deck and

jumped up and down and could not flip it over!

Coast Guard Testing

The second

aspect of safety is the capacity, flotation, and US Coast Guard approval.

This is the biggest improvement we made since taking over the company from Don

Warren in 2007. We have added flotation so the boat floats level when

swamped, followed all Coast Guard specs for construction capacity and motor

restriction, worked closely with the US Coast Guard, and even submitted our

boats for voluntary testing.

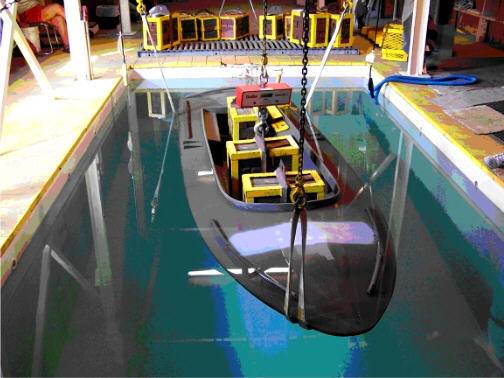

The first

phase of the coast guard testing is the capacity testing.† In this test, the boat is floated in a tank

and filled with 5 times the weight it is rated for.† For example, our 12í boat was filled with

1,500 POUNDS OF IRON and the 14í boat was filled with 2,500 POUNDS OF IRON and

both passed with flying colors!

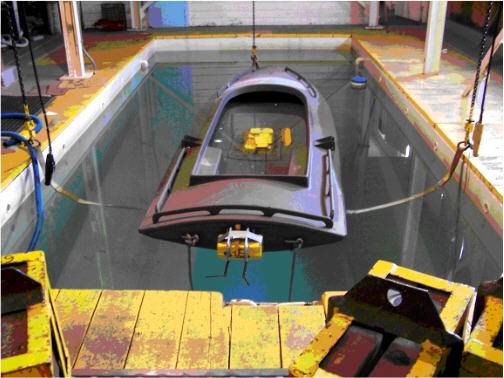

The second

phase of Coast Guard testing is the swamped flotation test.† This is to test the foam flotation in the

event that the boat becomes filled with water.†

In this test the boat is loaded with enough weight to simulate the

persons, motor, and gear that itís rated for.†

Then holes are drilled in the deck to let any trapped air out, and the

boat is filled with water.† The boat must

float level for 18 hours.† Our boats

excelled in this test, and actually popped up out of the water, shooting the

water out through the drain hole!

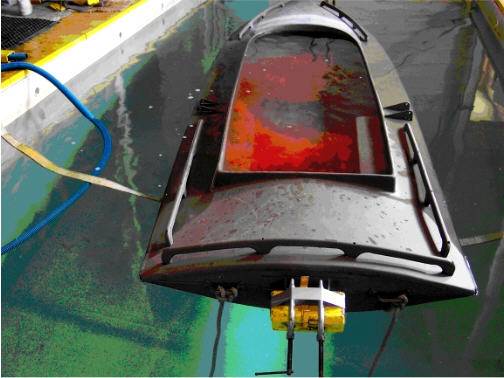

In order

to show the water being pushed out through the drain hole,

the Coast Guard filled the boat with red dye so the water could be seen being

pushed out of the drain.

At Classic Barnegat

Sneakboxes, we will take no shortcuts and cut no corners when it comes to your

safety!!!